Kitting

Built to your specifications, resulting in greater levels of productivity. Our kitting solutions provide your technicians with the parts they need, exactly where they are needed. With over 1000 kit variations built per year; Gexpro Services is your industry leader in specialty kitting solutions

Key Benefits

- Consolidation of many parts into single part number for full traceability

- Customizable Bill of Materials

- Reduction of handling and motion time by floor operators

- Guaranteed component stocking levels

What We Do

Production Kits

Installation Kits

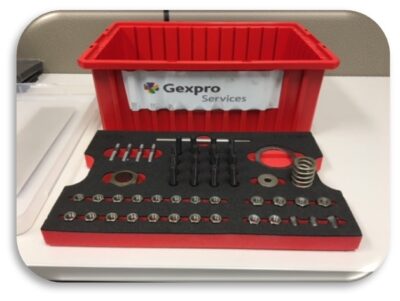

Foam Kitting

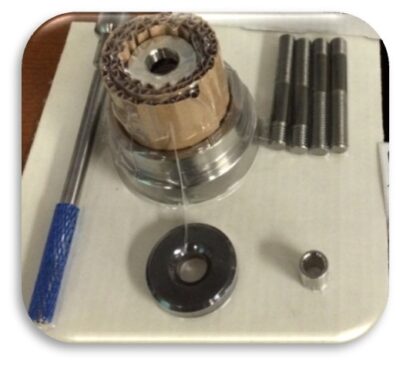

Repair Kits

Electrical Kitting

Large Scale Returnable

Production Kitting Services: We provide production kitting and assembly services of various products and components, offering cost-efficient solutions to companies of all sizes. We provide high-quality kitting, assembly and packaging solutions to a wide range of industries. Then the manufacturer’s associates build the final products using the supplied kits.

Installation Kitting service includes installation and setup of various applications at our logistics centers, prior to the delivery of equipment or devices. We utilize logistics centers throughout the world, we can them provide our standardized, high-quality kitting service for a variety of your equipment.

Foam Kitting: Gexpro Services provides custom foam kitting to create the ideal organizer in mobile form. A kit provides you with quick access and visual identification of all your necessary tools, parts, or other related components in one place and even on the go.

Our custom foam kits are the perfect fit for manufacturers and many other industries by providing an immediate assessment of all units, inventory control of parts for assembly, and an organized storage solution.\

Gexpro Services provides repair kits to support our customers aftermarket needs. Gexpro Services can build complex kits that include up to 100 different products. We work with our customers to identify the environment the kits will be sent to in order develop packaging suitable to product the products in those environments. With Gexpro Services repair kitting and packaging services, we carefully pack products using your packaging to represent a consistent brand to your customers.

Skin Packaging: Gexpro Services uses skin packaging technology and skin packaging for kitting various industry applications. Skin packaging can lock down your kit parts to a board or card and protects them during shipping and handling, instead of bagging parts for rebuild or spare part kits which can lead to loss or damage.

Electrical Kitting, or the pre-packaging of selected electrical and related components, is an effective way to cut total costs for all industries. Parts packages can be configured to include a few or many components as an individual SKU. Gexpro Services creates custom kitting solutions to reduce inventory and ordering errors and improve efficiency of customer processes.

Gexpro Services performs a variety of light duty services including control panel assembly, enclosure modifications, circuit breaker modifications, din rail cutting, fixture whip assembly, and more. Giving your business the agility to receive final assembles & focus on you customer.

Large Scale Returnable: Gexpro Services specializes in the engineering and fabrication of returnable packaging solutions. Gexpro Services delivers diverse engineering and fabrication capabilities to meet your packaging needs across many different industries. Gexpro Services produces various racks in ,multiple locations to meet your needs and production. Gexpro Services builds large scale production of custom racks, pallets and tote bins, such as metal pallets and even robotically loaded and unloaded racks. We are a preferred vendor of highly customized and precisely measured returnable packaging solutions across North America and the worlds.